Tools and Materials

AI-Powered CAD and Manufacturing Tools Offered by Nikalex

AI-Empowered CAD & Design Optimization

• Generative and AI-assisted design using tools such as Fusion 360 to reduce mass while maintaining or improving structural performance based on load cases and constraints.

• Design for Additive Manufacturing (DfAM) focused on weight reduction, stiffness optimization, and printability in titanium alloys.

Nikalex uses a range of the latest AI-powered tools to process and optimize CAD files, ensuring precision, efficiency, and innovation throughout the design-to-production workflow. These tools help automate complex modeling tasks, analyze stress and thermal properties, and generate advanced geometries that improve performance while minimizing material usage. By combining AI-driven design optimization with expert engineering knowledge, Nikalex transforms customer concepts into high-quality, manufacturable titanium components. The company also utilizes the Renishaw AM 400 machine for titanium 3D printing, enabling the production of intricate and durable parts with superior accuracy and surface finish.

Autodesk Fusion 360

Nikalex uses Autodesk Fusion 360’s Generative Design feature to create optimized and innovative CAD models that combine strength, lightweight efficiency, and manufacturability. By leveraging advanced algorithms and cloud-based computation, Nikalex processes design parameters such as material, load conditions, and constraints to automatically generate multiple geometry options. These generative shapes allow the company to explore complex titanium structures that would be difficult to design manually, resulting in high-performance, production-ready parts with reduced material waste and improved functionality. (Photo Credit: Autodesk Website)

AI-Optimized Titanium, Verified in Fusion 360

At Nikalex, we leverage Fusion 360’s generative design and simulation capabilities to drive our CAD and titanium component development. Beginning with your CAD model, we apply AI-driven generative optimization to refine geometry, improve load paths and minimise material use — all within the Fusion 360 environment.

The output model feeds directly into Fusion 360’s Simulation workspace, enabling us to validate structural performance under real-world conditions (static loads, impact, thermal stress) before committing to metal additive manufacturing. This seamless workflow—from generative design through simulation to manufacturability—ensures we deliver custom titanium parts with precision, strength and efficiency. (Picture Credit: Autodesk Website)

The Renishaw AM 400

Our titanium components are produced using advanced metal additive manufacturing systems such as the Renishaw AM400 — a professional-grade laser powder bed fusion machine engineered for precision and repeatability. With a 400-watt fiber laser, fine 20–100 µm layer capability, and support for aerospace-grade titanium alloy Ti-6Al-4V, this platform enables us to manufacture lightweight, high-strength parts that meet demanding structural and performance requirements.

Its calibrated laser control system, inert argon build environment, and SafeChange filtration technology ensure consistent part quality across complex geometries and high-detail builds. We work closely with manufacturing partners operating AM400 systems in facilities certified to ISO 9001 and ISO 13485 quality standards, giving our customers confidence that parts are produced to rigorous industrial and medical-grade protocols.

While Nikalex itself does not currently hold these certifications, we follow ISO-aligned practices and rely on certified partners to ensure compliance, traceability, and reliable titanium production. This combination of advanced equipment and qualified manufacturing partners allows us to deliver precision titanium components designed and optimized through AI-driven engineering.

Manufacturing Specifications (LPBF)

• Process: Laser Powder Bed Fusion (LPBF) on Renishaw AM 400 systems

• Build envelope: ~250 × 250 × 300 mm

• Layer thickness: 20–100 µm, selected based on geometry and performance

• Laser: 400 W ytterbium fiber laser with ~70 µm spot size

• Atmosphere: Argon inert environment with O₂ < 0.1% during build

• Powder handling: Inert loading, recovery, sieving, and controlled reuse

• Post-processing: Stress relief, heat treatment, machining, surface finishing

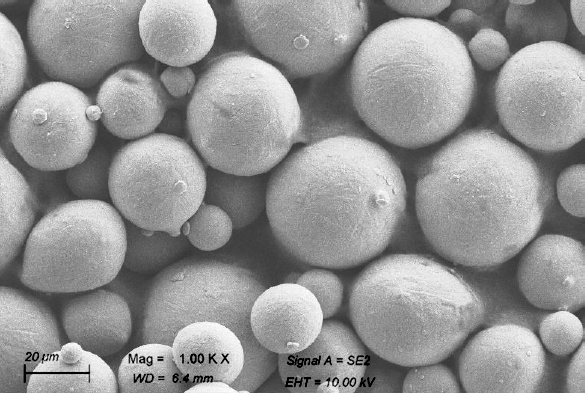

Material Specifications

(Ti-6Al-4V Grade 23 / ELI)

• Material: Ti-6Al-4V Grade 23 (ELI) titanium alloy

• Powder production: Plasma atomized, spherical morphology

• Particle size distribution: 15–53 µm

• Standards: ASTM F136, F1472, F3001, ASTM B348 Grade 23

• Powder properties: Hall flow ~28 s/50 g, bulk density ~2.4 g/cm³, tapped density ~2.8 g/cm³

Mechanical Properties (Room Temperature)

• Ultimate tensile strength: ~1180 MPa | Yield strength: ~1170 MPa

• Elongation: ~10–11% | Elastic modulus: ~114 GPa | Hardness: ~330 HV